MAY 2019

The Road to Producing PCBs

When it comes to the method of coating LPI solder mask onto the board, you have several options. In the Americas, screen coating is the most popular option, followed by spray coat and the latest – which is getting a lot of interest – inkjet solder mask (to be discussed in a future article.)

When it comes to the method of coating LPI solder mask onto the board, you have several options. In the Americas, screen coating is the most popular option, followed by spray coat and the latest – which is getting a lot of interest – inkjet solder mask (to be discussed in a future article.)

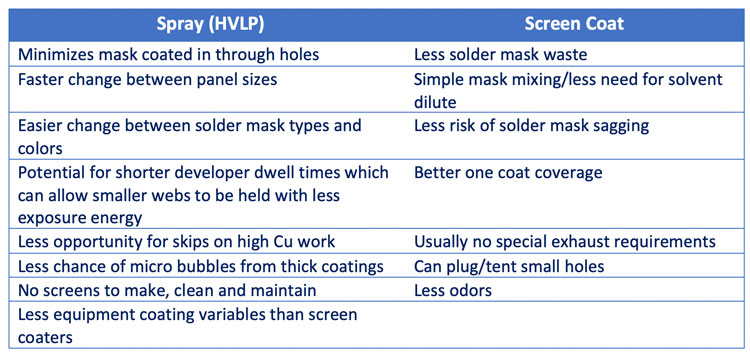

A frequently asked question is which method is best for coating LPI solder mask: screen or spray? The answer to this is not a simple one as there are pros and cons to each and it depends on the type of work produced. In fact, the best scenario may be to have both if space, money and environment were not factors. Below, is a chart showing some of the advantages of each.

As you can see above, each has specific advantages but there is no “best” solution for a solder mask coating application. Both screen and spray have their own unique advantages and disadvantages and high Cu traces pose challenges with each. Spray coating in North America accounts for about 15-20% of the coating applications; most still screen coat. Recently there has been more interest in spray to counter the increases in small hole/high aspect ratio panel designs in order to improve single-pass hole clearing performance. Some are considering a spray coater to supplement, not replace, screen printing. Adding inkjet solder mask to the equation will add additional options, as well.